Comparative Analysis: Continuous Pyrolysis vs. Traditional Pyrolysis

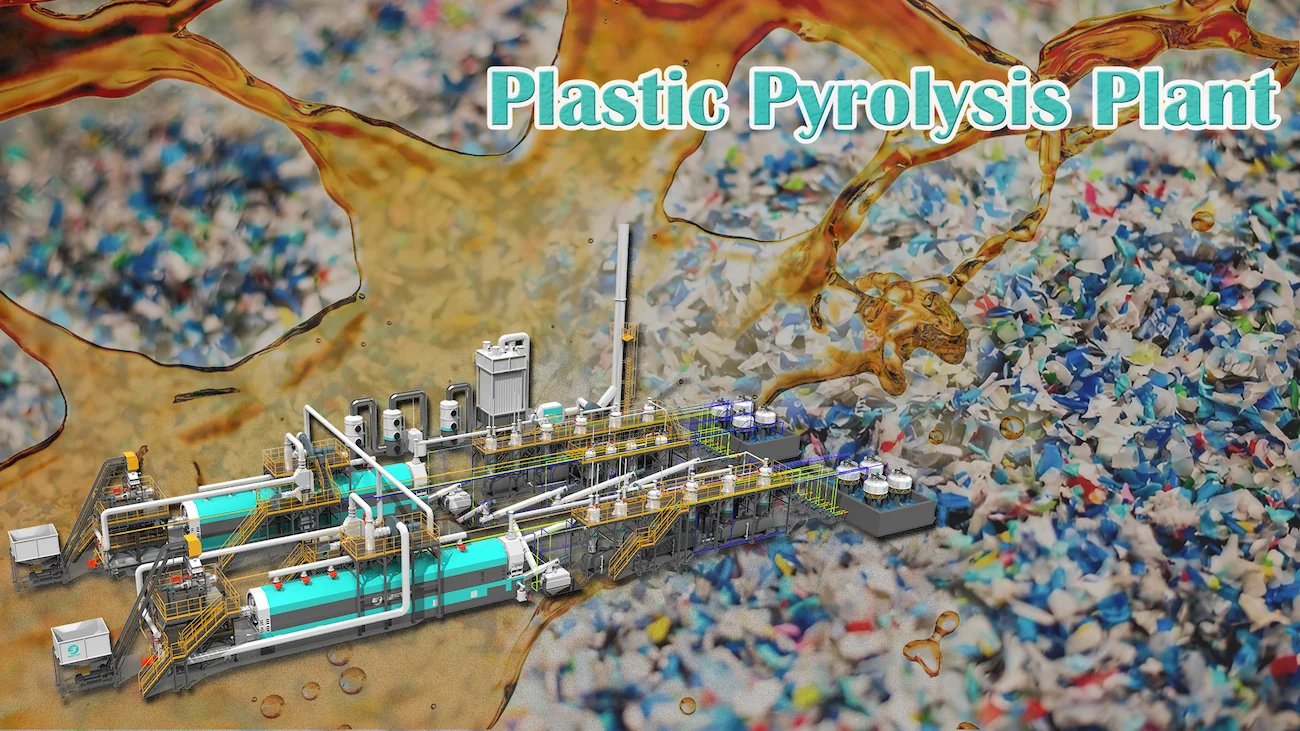

In the field of waste – to – energy and sustainable resource utilization, pyrolysis technology has emerged as a promising solution. Among the various pyrolysis options, continuous pyrolysis plants have been gaining more attention, especially when compared to traditional pyrolysis methods. In this article, we will conduct a detailed comparison, with a focus on the Beston pyrolysis plant as an example of a continuous pyrolysis plant, considering aspects such as efficiency, cost, and environmental impact.

Efficiency

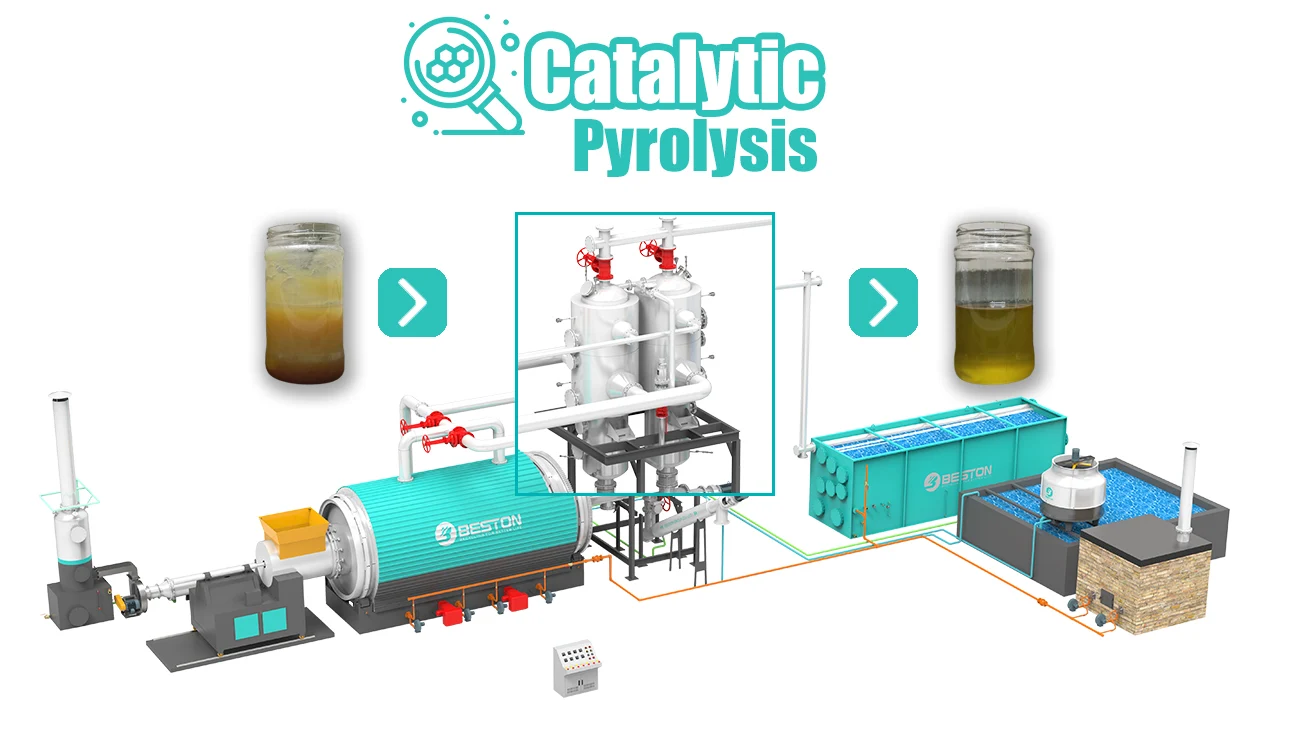

Continuous pyrolysis plant designed for uninterrupted operation. Their advanced systems enable a continuous feed of raw materials into the pyrolysis reactor. This means that there is no need for frequent stops and starts, which are common in traditional pyrolysis methods. As a result, the production process is much more streamlined. For instance, in a continuous pyrolysis plant, the heat – up time is minimized, and the reaction conditions can be maintained at an optimal level continuously. This leads to a higher yield of valuable products, such as bio – oil, bio – char, and syngas, within a shorter period.

Traditional pyrolysis methods often operate in a batch – mode. Each batch requires a significant amount of time for loading the raw materials, heating up the pyrolyss reactor, carrying out the pyrolysis process, and then unloading the products. The intermittent operation not only reduces the overall production capacity but also increases the energy consumption during the start – up and shut – down phases. Additionally, the inconsistent reaction conditions between batches can result in a less stable product quality.

Cost

When it comes to the initial investment, the pyrolysis machine price may seem relatively high. However, it’s essential to consider the long – term cost – effectiveness. For example, the Beston pyrolysis plant, despite its higher upfront cost, offers a lower cost per unit of production in the long run. This is because of its high – efficiency operation, which reduces the need for frequent maintenance and replacement of components.

In contrast, traditional pyrolysis methods, although they may have a lower initial pyrolysis machine price, often require more frequent equipment upgrades and repairs due to their stop – start operation. Moreover, the lower production efficiency means that the cost of producing the same amount of products is higher, considering the energy consumption and labor costs associated with each batch.

The continuous operation of a continuous pyrolysis plant also leads to lower operating costs. Since the process is more automated and requires less manual intervention, the labor cost is reduced. Additionally, the optimized energy usage in continuous pyrolysis plants, which maintain a stable temperature and reaction conditions, results in lower energy bills compared to traditional pyrolysis methods that experience energy – intensive start – up and cool – down cycles.

Environmental Impact

Continuous pyrolysis plants are generally more environmentally friendly. The continuous and controlled operation allows for better management of emissions. For example, the Beston pyrolysis plant is equipped with advanced gas – purification systems that can effectively remove harmful pollutants, such as sulfur dioxide, nitrogen oxides, and particulate matter, from the pyrolysis gases. This ensures that the emissions meet or even exceed the strict environmental standards.

Traditional pyrolysis methods often struggle with emissions control. The intermittent operation and less – precise control of reaction conditions can lead to the release of more pollutants into the atmosphere. Moreover, the lower efficiency means that more waste materials may not be fully converted into useful products, resulting in a higher environmental burden in terms of waste disposal.

In conclusion, continuous pyrolysis plants, represented by the Beston pyrolysis plant, have significant advantages over traditional pyrolysis methods in terms of efficiency, cost – effectiveness, and environmental friendliness. Although the initial investment in a continuous pyrolysis plant may be higher, the long – term benefits far outweigh the costs. As the demand for sustainable waste – to – energy solutions continues to grow, continuous pyrolysis plants are expected to play an increasingly important role in the industry.